With a bold approach to sustainability, Armstrong and Rheaply are turning waste challenges into growth opportunities.

Armstrong World Industries (Armstrong) is a leading manufacturer of building products, specializing in innovative and sustainable ceiling and wall solutions. With a mission to create a healthier, more productive environment for its customers, Armstrong is committed to designing products that enhance interior spaces while minimizing environmental impact. With respect to product waste, their sustainability efforts include reducing manufacturing waste, designing products with low-embodied carbon materials, and implementing circular economy business models.

The Ceiling Recycling Program is one of Armstrong’s long-standing sustainability initiatives. Armstrong customers are encouraged to return used ceiling tiles for recycling into new Armstrong products. Additionally, they prioritize sustainable materials, incorporating recycled content and low-embodied carbon materials into their designs. Armstrong is also dedicated to designing products that reduce operational carbon from heating and cooling buildings with their recent product release, Templok® Energy Saving Ceilings. Their commitment to innovation and sustainability makes them a leader in the building products industry.

Setting the stage for innovation

In 2023, Armstrong partnered with Rheaply to transform waste into valuable resources. This collaboration aimed to explore new sustainable end markets by repurposing Armstrong products that were previously destined for landfills after their initial use. The initiative aligns with Armstrong’s 2030 sustainability objectives, including reducing absolute waste from operations, increasing product circularity, and contributing to a broader commitment to lowering the company’s carbon footprint while driving innovation in resource management.

“The decision to engage Rheaply in supporting our product take back and end-market development has been incredibly educational and fruitful. They seamlessly connected with our team to add immediate expertise, and their values-aligned, enthusiastic approach has made this one of the most enjoyable teams that I’ve ever had the pleasure to work with. They are nimble, knowledgeable, and effective. The world would be a different place if all collaborative learning felt this way!”

Arktura Ventures/Armstrong World Industries

Crafting a blueprint for market expansion

Armstrong faced the challenge of maximizing resource efficiency in an industry where traditional waste management often overlooks lightweight materials. Materials such as thermal insulation and ceiling tiles are often neglected in recycling efforts because landfill costs are calculated by weight. These types of low-density materials don’t generate high disposal fees compared to heavier materials like metals, concrete, drywall, and wood. However, Armstrong recognized the importance of addressing this gap. The time had come to develop innovative solutions that not only diverted these materials from landfills but also unlocked new value from what was previously considered waste.

To address this challenge, Armstrong and Rheaply developed a comprehensive strategy to identify and engage potential end markets for repurposed materials. The approach involved:

- Market Categorization: The team systematically categorized potential markets based on technology readiness, market size, and strategic fit. This process allowed Armstrong to prioritize high-impact opportunities and allocate resources effectively.

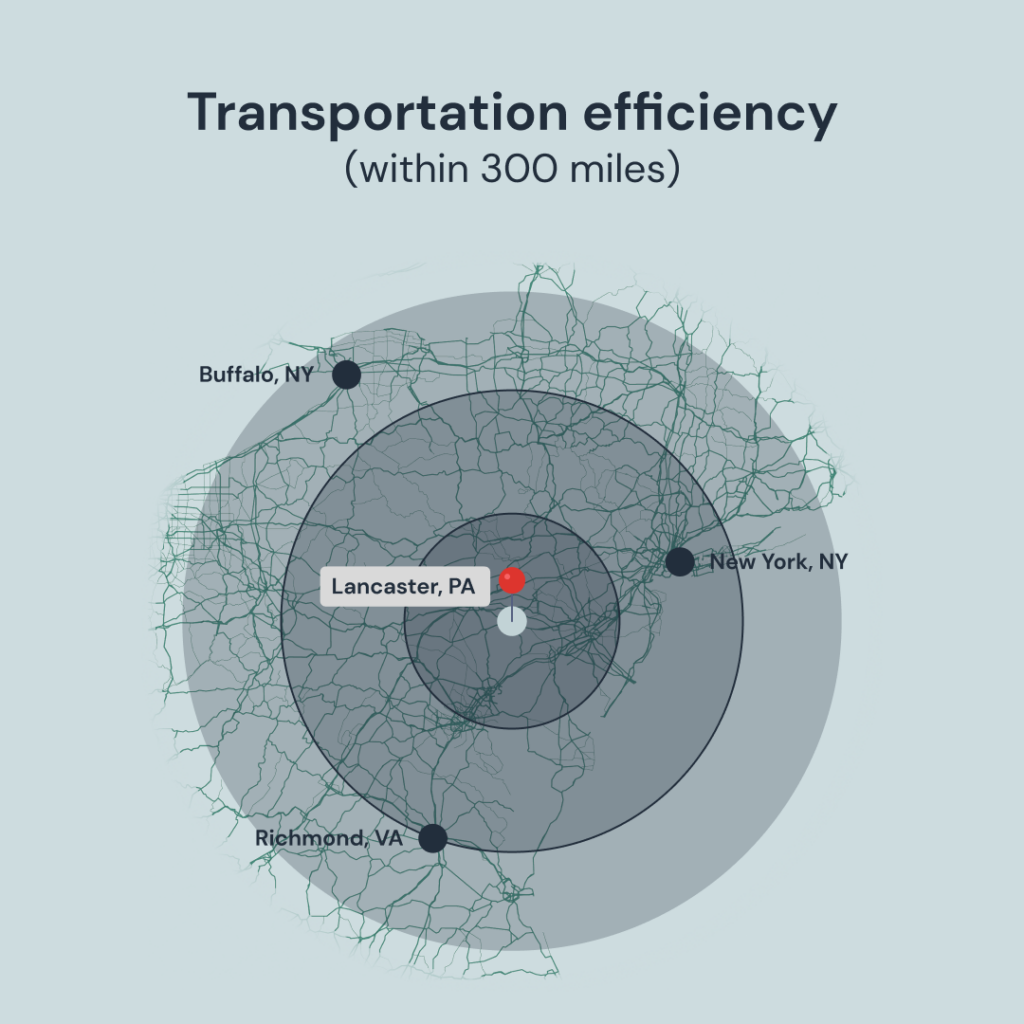

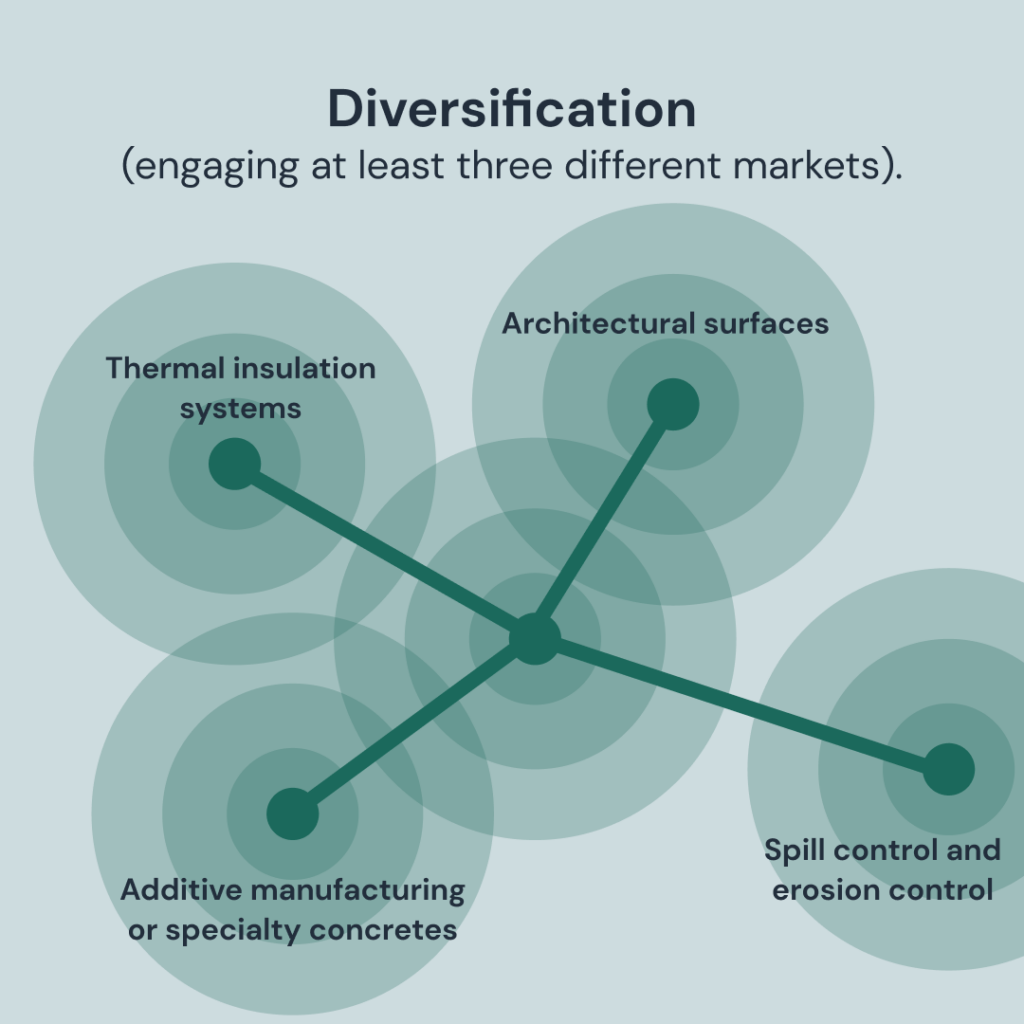

- End-Market Exploration: The collaboration focused on exploring a variety of industries, including construction, manufacturing, and agriculture, to find suitable applications for repurposed materials. This exploration was guided by the “Rule of Threes”—a strategic framework coined by the Construction and Demolition Recycling Association. This framework emphasizes transportation efficiency (within 300 miles), timely market engagement to combat storage costs (sell or donate materials within three weeks), and diversification (engaging at least three different markets).

- Material Perception Shift: A significant challenge is changing the perception of “waste materials” to make them appealing to potential buyers. The team tackled this by developing detailed product specification documents and product samples, allowing prospective partners to visualize the materials as valuable resources rather than waste. This strategy was crucial in opening doors to more serious market engagements.

- Pilot Testing and Feedback Loops: Armstrong conducted pilot tests with select partners to assess the viability of repurposed materials in real-world applications. These tests provided critical feedback, enabling the team to refine their approach and better align the materials with market demands.

- Cross-Industry Collaboration: The strategy also involved building relationships with key players across different sectors. By fostering these connections, Armstrong was able to identify joint opportunities that aligned with both the company’s sustainability goals and the partners’ operational needs.

Through these detailed steps, Armstrong and Rheaply crafted a robust blueprint for market expansion, laying the foundation for long-term sustainability and innovation.

Looking within your operations

Throughout the blueprinting process, Armstrong and Rheaply did not overlook one of the most effective opportunities for extending the life of sold products – a company’s own operations. The highest and best use of materials can often be found within your own manufacturing process and business segments. Recycling by-products and waste materials into new products is not new for Armstrong.

The company’s origins in the late 19th century involved hand-cutting corks for bottle stoppers. The cork-cutting process created significant amounts of shavings, which initially posed a disposal challenge. Armstrong turned this challenge into a business opportunity by discovering a “new” product at the time—linoleum, which was made from cork shavings and linseed oil. What started as a waste problem evolved into a new, highly valuable market for Armstrong. This historical example highlights the company’s long standing ability to turn waste into valuable resources—a tradition that continues today through its circular economy initiatives.

Armstrong is continuously working towards increasing the recycled content across their product lines. This internal-first approach allows Armstrong to reduce waste and maximize the value of materials already in circulation, fully utilizing their internal capabilities as the foundation for sustainable innovation.

Collaborative synergy: The power of partnership

The project’s success was deeply rooted in the collaborative effort between Rheaply and various Armstrong teams, including Arktura Ventures, Research and Design, Corporate Sustainability, Procurement, and Sales. Each team played a crucial role, contributing unique expertise that ensured a comprehensive approach to market exploration and product development. The collaboration revealed not only the potential of new external markets but also the untapped opportunities within Armstrong’s own operations, reinforcing the value of internal resource optimization.

Breakthrough insights and the road ahead

This project is a testament to the power of collaboration and strategic innovation in driving sustainability. By transforming waste into opportunity, Armstrong and Rheaply have not only advanced Armstrong’s sustainability efforts but have also set a new standard for the industry.

Here are key takeaways for organizations aiming to extend the lifespan of their products and waste materials:

- Your team and partners are the bedrock of your success: Engage diverse perspectives and prioritize transparency and collaboration. A strong, creative team dynamic is essential. When reaching out to potential partners, recognize the creativity of recyclers and the importance of industry collaboration. If viable end markets are identified, resourceful recyclers will design solutions to meet those needs.

- Embrace rejections as stepping stones to success: When engaging with organizations, casting a wide net is crucial. The broader your reach, the greater your chances of finding partners who share your vision and are open to innovation. While most responses may be “no,” it’s important to view these rejections as part of the process. Each “no” brings you closer to the meaningful “yeses” that will drive your project forward. Stay resilient and focused on your goals.

- Detailed questions lead to real opportunities: When potential partners start asking about quality control, material volumes, transportation, and costs, you’ve reached a critical tipping point. These questions show that they are beginning to see the potential and are invested in the journey, recognizing waste as a valuable resource.

As the journey continues, the lessons learned and the networks built will serve as catalysts for further breakthroughs in the circular economy for the built environment.

Want to meet with Rheaply’s experts to discuss a custom circular economy business model for your organization?

by Courtney Newman

by Courtney Newman

by Derek Doeing

by Derek Doeing