Manufacturing Inventory Tracking System

Rheaply puts reuse on the table for every organization.

Manufacturing Inventory Tracking System

Manufacturing inventory tracking systems leverage a fusion of sophisticated software and advanced technology to facilitate real-time monitoring and management of inventory. They offer an accurate, up-to-the-minute overview of stock levels, from raw materials to finished products, throughout the supply chain. For this reason, they’ve become an indispensable tool for effective inventory management in manufacturing.

At its core, a manufacturing inventory tracking system is akin to a dynamic inventory ledger that updates on a continual basis. It meticulously records existing stock levels and tracks the inflow of new materials and outflow of finished goods, enabling precise inventory control and forecasting. In manufacturing, this ability to closely track goods is of the utmost importance.

By determining how to most effectively meet current and future demands, companies can avoid overproduction and its associated costs. Those without an inventory tracking system may not always be aware of their exact stock levels, which can lead to overstocking and stockouts. The former can inflate inventory holding costs, waste warehouse space, and increase the risk of stock becoming obsolete. Stockouts have the potential to harm the company’s reputation.

It should come as no surprise, then, that more and more businesses in the manufacturing realm are investing heavily in tracking software. These solutions can help solve a myriad of issues, including:

- Inaccurate inventory counts leading to discrepancies.

- Inefficient use of warehouse space due to overstocking.

- High holding costs associated with excessive inventory.

- Risk of stock becoming obsolete or expiring.

By facilitating FIFO (First-In-First-Out) or LIFO (Last-In-First-Out) strategies, an inventory tracking system can also minimize the risk of stock obsolescence. What’s more, this type of software is instrumental in developing, implementing, and improving reuse strategies, a key element in achieving sustainable manufacturing practices.

So with all that being said, why are some businesses refusing to adapt? Why do so many organizations still rely on outdated, manual tracking processes? There are a number of reasons for this, mainly revolving around cost. Many organizations simply lack the financial resources to invest in system implementation and maintenance.

Some are also intimidated by the prospect of transitioning to a new management system. However, with the right tools and education, more and more companies are finding the skills and confidence to upgrade their systems and maintain better control over their inventory. This has led to countless benefits for companies, customers, and stakeholders alike.

Inventory management

Inventory management systems are critical to controlling and optimizing inventory levels. They help in tracking goods throughout the entire supply chain, from manufacturing and warehousing to distribution and delivery. As businesses increasingly adopt the circular economy model, several new types of inventory management systems are entering the market, each with unique features and benefits. The most popular systems include:

- Manual Inventory Management Systems: These systems record inventory the old-fashioned way, counting each item manually. Manual systems are typically used by small businesses with less complex inventory needs. Despite being labor-intensive and prone to human error, they offer a low-cost entry point into inventory management and remain an attractive option for many.

- Barcode Scanning Systems: Barcode scanning systems use barcode technology for tracking inventory. Each item or batch is assigned a unique barcode that can be scanned during various stages of the supply chain. This enables real-time tracking and reduces errors.

- Radio Frequency Identification (RFID) Systems: Similar to barcode systems, but more advanced, RFID systems use electromagnetic fields to automatically identify and track tags attached to inventory items. They bring real-time, highly accurate inventory tracking to the table. Unlike barcode systems, they don’t require line-of-sight to read tags.

- Just-in-Time (JIT) Inventory Systems: JIT systems align raw material orders from suppliers directly with production schedules, reducing the amount of stock held and minimizing storage costs.

- ABC Analysis Systems: These systems categorize inventory into three categories (A, B, C) based on its value and turnover frequency, allowing businesses to apply different management strategies for each. ABC analysis systems can contribute to resource optimization in a circular economy by ensuring high-value items (Category A) are efficiently managed and lower-value items (Category C) are minimized or eliminated.

- Automated Inventory Management Systems: Automated systems automate the entire inventory management process, leveraging artificial intelligence and machine learning algorithms to perform otherwise time-consuming tasks. They offer accurate forecasting, seamless tracking, and automated reporting, which significantly reduces errors and enhances efficiency.

* *Cloud-Based Inventory Management Systems:* Cloud-based systems offer real-time access to inventory data from any location. They are capable of supporting circular economy practices by enabling real-time tracking of inventory across multiple locations. One of the best things about cloud-based systems is that they can be accessed anywhere.

Best Inventory Management Software For Manufacturing

The importance of effective inventory tracking has been brought to the forefront in recent years, especially as businesses transition to the circular economy. Specialized software can streamline operations and ultimately contribute to sustainability. The following are some of the best tracking solutions and how they contribute to the circular economy and sustainability:

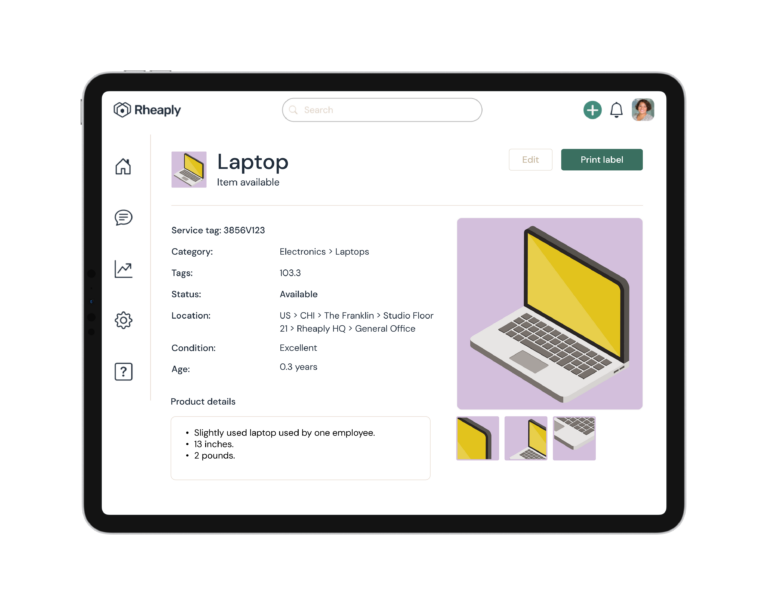

- Rheaply’s Inventory Management Solution is designed to simplify the way companies track stock levels. With Rheaply, users can track and manage assets from a single platform. They can also look for ways to reuse existing resources, minimizing their carbon footprint and saving on production costs.

- Oracle NetSuite: NetSuite’s inventory management system offers end-to-end visibility into the supply chain. Its robust suite of inventory control and warehouse management tools include demand planning, inventory tracking, and automated purchasing. NetSuite supports circular economy principles by facilitating accurate inventory forecasting.

- Fishbowl Manufacturing: This comprehensive solution features advanced work order management and standard cost tracking. Its real-time updates on inventory levels help prevent stockouts and overstocking, minimizing waste. Fishbowl’s serialization and lot tracking capabilities can also support circular economy benefits for business by providing detailed product lifecycle information.

- SAP Business One: Known for its robust ERP solutions, SAP Business One provides an integrated inventory management module with multi-warehouse management and much more. Its detailed tracking and reporting capabilities can aid businesses in identifying and implementing circular economy and sustainability strategies, such as resource optimization and waste reduction.

- Zoho Inventory: Zoho Inventory excels in order tracking, warehouse management, and multi-channel selling. It offers insights into inventory turnover—this is crucial to maintaining optimal stock levels and reducing waste. The software can track products through their lifecycle, which supports the circular economy by informing users when and if items should be replaced.

- Infor CloudSuite Industrial (SyteLine): This robust software suite comes with advanced inventory and quality management tools. It helps manufacturers maintain accurate inventory records; it also automates forecasting and planning. By minimizing overproduction and excess inventory, this software contributes greatly to users’ sustainability initiatives.

These are just some of the quality software solutions that exist today to help businesses keep better track of their inventory and reduce their environmental impact. While the circular economy benefits for business are clear, organizations should outline their specific needs in order to get the most out of their software of choice.

Circular Economy Benefits For Business

When integrated, manufacturing inventory tracking and order management systems create a streamlined process that effectively bridges the gap between production and order fulfillment. This integration optimizes operations and supports sustainable practices that are in line with the principles of the circular economy.

Manufacturing inventory management revolves around tracking materials and finished goods throughout the production cycle. The best inventory management software for manufacturing thus provides real-time visibility into stock levels, allowing manufacturers to accurately forecast demand and more easily manage their resources.

An order management system, on the other hand, deals with the sales aspect. It’s used to manage customer orders from receipt to delivery. These systems track the order status, coordinate with various departments, and update customers about their order progress. When used in conjunction, inventory and order management systems provide a holistic view of the supply chain.

To better illustrate this process, consider a manufacturing inventory example in which a bicycle manufacturing company utilizes an inventory management system to track bike components. When a customer places an order for a bicycle, the order management system kicks in, relaying the order details to the production department.

Ideally, the inventory management system will adjust stock levels based on the pieces used for that order. It can also trigger a replenishment order if the stock falls below a certain level. This real-time coordination between the two systems ensures that production never halts due to lack of inventory and that no excess stock is left unused or wasted.

Such integration capabilities also enhance the customer experience. Because the order management system has updated access to inventory data, it can provide accurate delivery estimates to customers and promptly inform them of any potential delays due to stock unavailability.

By synchronizing production with demand, integrated systems can significantly reduce waste—a crucial aspect of circular economy practices. Overproduction is minimized, and materials are ordered just when needed, which means less raw material waste and fewer finished goods sitting idle or becoming obsolete. This is key to not only cutting costs, but promoting sustainability.

Researching and comparing your options is the best way to find the tool that’s best for your company. By taking the time to do so, you can improve your inventory management process and contribute to more eco-friendly practices in the supply chain.