Manufacturing Inventory Management System

Rheaply puts reuse on the table for every organization.

Manufacturing Inventory Management System

A manufacturing inventory management system is a valuable tool for businesses. It serves as the cornerstone of successful production processes and efficient supply chain management. A system like this provides a holistic, real-time view of a company’s raw materials, work-in-progress goods, and finished products, ensuring optimal stock levels at all times.

Because effective inventory management is so crucial to business success, especially in the manufacturing realm, more and more businesses are adopting effective, automated systems for keeping up with their inventory. These systems help to ensure that organizations are equipped with the right quantity of goods at the right time, preventing stock outs that could lead to lost sales, or overstock that could inflate storage costs. They also aid in monitoring production flows and making data-driven decisions.

The role of inventory in supply chain management is equally critical. It serves as a bridge between production and distribution, influencing the operational efficiency of the entire supply chain. By maintaining an optimal level of inventory, businesses can prevent disruptions and promote the smooth flow of goods from production facilities to end consumers. A well-managed inventory can enhance supplier relationships and contribute to business competitiveness.

Finding the right inventory system is vital to transforming inventory management. With a growing number of quality solutions on the market today, choosing between them can be difficult. However, by outlining their specific needs and objectives, businesses can determine which systems are right for them. This is key to getting more out of their existing processes.

Rheaply allows users to gain deeper visibility into their operations, which can be extremely helpful for those looking to optimize their inventory levels. By promoting reuse and recycle principles, Rheaply can be used alongside manufacturing inventory management systems so that users can keep a closer eye on their inventory and determine how to achieve greater sustainability in their supply chain activities.

Types of Inventory Management Systems

Inventory management is especially critical in the manufacturing space, where maintaining optimal inventory levels at all times is paramount for business success. There are several different types of inventory management systems that companies use to optimize their operations. Each comes equipped with unique features and applications.

Manual inventory management systems were the first type of inventory management systems. Despite significant advancements in technology, some small businesses still use them due to their low operating costs and ease of use. Manual systems involve physically counting and recording inventory and can be as straightforward as maintaining a ledger or an Excel spreadsheet. Although cost-effective, manual systems are labor-intensive, prone to human error, and lack real-time tracking.

Barcode systems are a step up from manual systems and have become a standard in many industries, including manufacturing. They use barcode labels attached to items, which are scanned using barcode readers to update inventory levels automatically. This system significantly reduces errors and speeds up the process of inventory counting. However, barcode systems require investment in equipment and training.

Automated inventory management systems, often integrated with manufacturing tracking software, are the most advanced systems. They employ technologies such as RFID (radio frequency identification) and IoT (internet of things) to monitor inventory levels in real time. They can also automate reordering processes, and even predict future demand based on historical data.

Manufacturing inventory management greatly benefits from automated systems. In addition to real-time inventory tracking, these systems can monitor the entire manufacturing process, from raw materials to finished goods. For instance, manufacturing tracking software can provide a granular view of work-in-progress inventory, identify bottlenecks, and suggest process improvements.

Advanced systems can also integrate with other business operations, creating a connected and streamlined ecosystem. This integration allows for improved forecasting and overall operational efficiency. By researching the various types of inventory management systems and their respective integration capabilities, businesses can find the most effective tools for their unique needs.

Inventory Management Techniques

Inventory management techniques are fundamental to the success of manufacturing businesses. Different approaches can be used depending on the company’s needs, goals, and complexity of operations. Three popular techniques are Just-In-Time (JIT), Economic Order Quantity (EOQ), and Safety Stock. Each deals with different aspects and types of inventory, ranging from raw materials to finished goods.

Here’s an explanation of the 3 types of inventory management techniques:

- JIT: JIT is an inventory management technique aimed at minimizing inventory costs by reducing the amount of inventory involves ordering and receiving inventory for production and customer sales just as it is needed, reducing inventory storage and holding costs. This technique is beneficial for industries with fast-moving inventory or those with products that have a short shelf life. However, it requires accurate forecasting and reliable suppliers to avoid stockouts.

- EOQ: EOQ is a model that determines the optimal order quantity that minimizes the total inventory holding costs and order costs. It’s best for businesses with consistent demand and lead times.This model can help to determine the optimal quantity of raw materials to order, the best batch size for production (work-in-progress inventory), and the ideal amount of finished goods to keep on hand.

- Safety Stock: Safety stock is extra inventory held to guard against variability in demand and/or supply. It acts as a buffer to mitigate the risk of stockouts. Safety stock levels are generally determined based on forecasting accuracy, supplier reliability, and the acceptable risk of a stockout. Across the main 7 types of inventory (raw materials, work-in-progress, finished goods, maintenance/repair/operations (MRO), goods-in-transit, cycle inventory, and safety stock), safety stock is a category of its own, but it can be applied to raw materials, work-in-progress, and finished goods as a protective measure.

Best Inventory Management Software

Manufacturing inventory software provides a comprehensive way for businesses to manage their inventory, streamline operations, and improve efficiency. There’s a wide range of options available on the market, each catering to different organizations with different needs. The following are some of the best inventory management software:

- SAP Business One: SAP Business One is a robust ERP system with powerful manufacturing inventory software features. Its inventory management module allows for real-time tracking of stock levels and transactions, automated data entry, and forecasting. It also integrates with other modules to offer a holistic view of business operations.

- Oracle NetSuite: Oracle NetSuite offers a cloud-based inventory management solution suitable for mid-sized to large businesses. Key features include demand planning, warehouse management, real-time inventory tracking, and integration with procurement and sales modules. NetSuite’s scalability and customization options make it adaptable to organizational growth.

- Fishbowl Marketing: Fishbowl Manufacturing is a cost-effective solution for small to medium-sized businesses, especially those transitioning from manual or basic inventory systems. This software is particularly well-suited for manufacturers looking for an easy-to-use, yet comprehensive inventory management solution.

- Infor CloudSuite Industrial (SyteLine): Infor CloudSuite Industrial offers an end-to-end manufacturing solution with strong inventory management features. It provides real-time inventory visibility, advanced planning, and scheduling features, and supports multi-site operations. Its robust capabilities make it a suitable option for mid-sized to large manufacturers in complex, discrete manufacturing industries.

- Epicor ERP: Epicor ERP includes a wealth of robust inventory management features. Chief among them are automated procurement and sophisticated forecasting. Epicor’s scalability and industry-specific solutions make it an excellent choice for both small businesses and large enterprises across various manufacturing sectors.

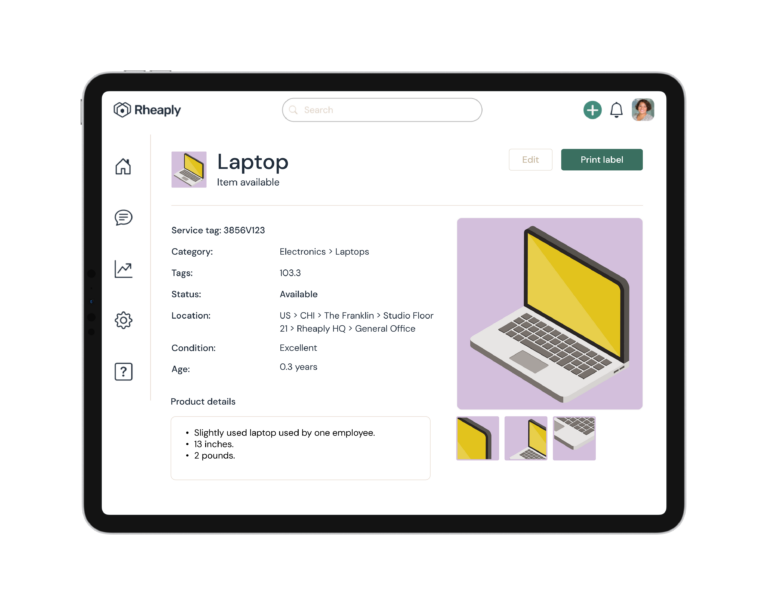

- Rheaply: With Visibility by Rheaply, you can regain control of all workplace resources from large-scale equipment down to individual assets. This is an excellent choice for organizations that are focused on sustainability and reuse.

When comparing the best inventory management software for manufacturing, it’s important for organizations to consider their specific needs. Some solutions are better suited for certain types of business needs than others.

Impact of Inventory Management on Manufacturing Organizations

The impact of inventory management on a manufacturing organization can be profound. These systems influence just about every aspect of business, including efficiency, profitability, and customer satisfaction. A well-implemented system can fundamentally transform the way manufacturing companies go about their daily operations.

To gauge system effectiveness, businesses should leverage data analytics and pay close attention to certain key performance indicators (KPIs). KPIs serve as an objective measure of efficiency. For example, inventory turnover, which looks at how often inventory is sold and replaced over a specific period, is a critical KPI in manufacturing. High inventory turnover generally indicates a successful balance between demand and supply.

Another significant KPI is stockout rate, which shows how frequently a business runs out of a product. High stockout rates can disrupt production schedules and lead to lost sales, damaging customer relationships. When that happens, businesses may need to refine their inventory forecasting or consider maintaining safety stock for critical items.

Data analysis plays a major role in inventory optimization. It offers companies valuable insights into different aspects of inventory management. For instance, businesses can use data analysis for accurate demand forecasting. By analyzing historical sales data, identifying trends, and factoring in variables like market conditions and seasonal fluctuations, they can anticipate future demand and adjust their inventory levels accordingly.

Analysis can also aid in assessing supplier performance because it can be used to evaluate parameters such as on-time delivery and overall reliability. This information can help businesses negotiate better terms and identify alternative suppliers if necessary.

Becoming familiar with the ins and outs of the inventory management process is crucial for those that are just getting started using inventory management systems or that are otherwise looking to optimize operations. It can also be helpful to view a manufacturing inventory example to get a better idea of how KPIs can be monitored using specialized software.