Asset Inventory Management Software

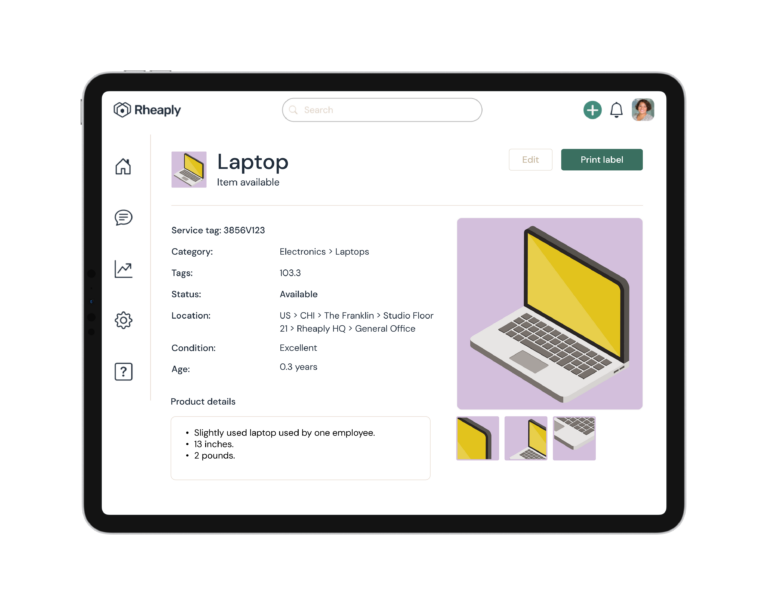

Rheaply puts reuse on the table for every organization.

Inventory Management Software For Manufacturing

The manufacturing industry has always been a dynamic sector, defined in large part by rapid adaptations to technological advancements and market trends. In recent years, this space has undergone significant changes driven by factors such as globalization and automation. As such, it has become crucial for businesses to modify their inventory management systems to address these evolving needs.

Inventory management software for manufacturing helps make that possible. Integrating advanced technologies like AI, the Internet of Things (IoT), and robotics in manufacturing processes, inventory system software helps companies optimize their workflows.

One of the key challenges that businesses face—and that can be addressed with a robust manufacturing inventory management system—is how to handle complex supply chains. With suppliers, manufacturers, and customers spread across the globe, businesses often require an inventory system to track the movement of goods and ensure timely delivery.

Additionally, the growing emphasis on customization and personalized products has led to a shift towards smaller, more frequent production runs. This means that businesses today need flexible and responsive solutions that can accommodate customer needs and fluctuating market demands. By leveraging real-time data, modern inventory management software like that offered by Rheaply enables businesses to minimize stockouts or overstock situations.

Sustainability has also emerged as a significant concern in the manufacturing sector, with more organizations looking for ways to minimize their impact on the environment. In response to this emphasis on eco-friendly solutions, inventory management systems today are playing an increasingly vital role in helping businesses maintain optimal inventory levels.

On one hand, companies must ensure they have adequate stock to meet current customer demand—on the other, they want to avoid overstocking, as this can lead to underutilization and, ultimately, increased waste. Inventory management software helps manufacturing companies stay on track and forecast future needs. This not only saves them money, but helps contribute to a more sustainable future.

Impact of Inventory Management on Manufacturing Organizations

Automating inventory management processes is a convenient way for businesses to gain greater control of their workflows. It allows them to optimize their operations, reduce costs, and improve overall performance—truly, the potential impact of inventory management on a manufacturing organization cannot be overstated. The benefits of automation include:

- Increased Efficiency: One of the primary advantages of automating inventory management processes is the increased efficiency it brings to the table. Businesses that eliminate manual tasks tend to save time and resources. This improved efficiency can also translate into faster order processing and boosted customer satisfaction.

- Reduced Human Errors: Manual inventory management processes can be highly error-prone, leading to inaccurate stock records and potential financial losses. However, by automating manual tasks, inventory software helps to minimize the likelihood of errors by ensuring that all data entries are accurate, consistent, and up to date.

- Real-Time Data Access: The implementation of manufacturing tracking software enables businesses to gain real-time access to critical inventory data, which is essential for informed decision-making. Real-time visibility allows organizations to monitor stock levels, track the movement of goods across the supply chain, and identify potential bottlenecks or inefficiencies in their processes.

- Improved Forecasting and Demand Planning: Enterprise inventory management software can help organizations anticipate future demand patterns and make more accurate predictions. This, in turn, allows them to optimize their inventory levels and better prepare to meet the evolving needs of their customers.

- Enhanced Collaboration and Communication: Automating inventory management processes can also have a positive impact on collaboration and communication within an organization. Manufacturing inventory software provides a centralized platform for data and makes it easier for all teams and departments to access the information they need.

These are just some of the ways that inventory management software can benefit organizations. It’s important for businesses to experiment with different tools and solutions to find the features that work best with their unique workflows, maximizing their ROI.

Manufacturing Inventory Example

In today’s data-driven world, inventory management software plays a key role in helping companies make informed decisions about their stock levels. Whether they’re in search of the best inventory management software for manufacturing or otherwise, businesses across industries can benefit from being able to automatically track and manage their assets.

One of the main reasons organizations choose to implement this type of software is that it can seamlessly facilitate data-driven decision-making. By collecting, processing, and analyzing large volumes of data, these solutions can help businesses identify patterns and anomalies in their supply chain operations. This ultimately allows them to save money and cut carbon emissions by scaling back on production when necessary.

Accurate demand forecasting is another important element involved in manufacturing software. It analyzes historical sales data and other relevant factors to make accurate predictions about future demand patterns, allowing users to adjust their inventory levels accordingly. Inventory management software for a small manufacturing business can be especially helpful in this regard, as small companies often lack the time and resources to handle forecasting manually.

Maintaining optimal inventory levels is a delicate balancing act for manufacturing businesses. Holding too much inventory can lead to increased carrying costs, while holding too little can result in stockouts and lost sales. Inventory management software can help organizations find this perfect balance.

For instance, consider a business that produces several product lines and works within a multifaceted supply chain. They implement specialized software to gain real-time visibility into the entire chain, from raw material procurement to finished product distribution. The organization can then monitor inventory levels and work to make things more efficient across the board. This manufacturing inventory example demonstrates the vital role that software plays in striking the right balance between costs and stock levels.

Inventory in Supply Chain Management

Inventory in supply chain management refers to the inventory stock levels maintained by an organization or group within the supply chain. Proper inventory management encompasses the appropriate handling of raw materials and finished goods. It also covers the processes involved in procuring, storing, and distributing these items. Effective inventory management helps businesses maintain optimal stock levels and improve customer satisfaction.

To cater to the specific needs of manufacturing businesses of different sizes and industries, there is a variety of customizable inventory management software options available on the market today.

- Raw Material Inventory Management Software: This type of software is designed to help businesses manage their raw material inventory more effectively. It offers real-time insights and visibility into stock levels to help companies source the materials they need and avoid stocking up on unnecessary items.

- Work-in-Progress Inventory Management Software: As the name implies, work-in-progress inventory refers to items that are currently being manufactured or assembled, but are not yet finished goods. This type of software allows users to monitor the progress of their production processes, track the movement of items through various stages, and make sure that production schedules are on track.

- Finished Goods Inventory Management Software: This software helps users manage the inventory of completed products that are ready for sale or distribution. Finished goods software is also great for optimizing distribution strategies and determining what, if anything, should be changed at the end of the production process.

Different types of software may be better suited to different types of inventory management. For example, a business that’s looking for help conducting periodic inventory management might look specifically at solutions that automate stock counting at regular intervals, such as a monthly or quarterly basis.

Sustainability in Logistics and Supply Chain Management

The integration of inventory management software with logistics supply chain management is crucial for achieving a streamlined and efficient manufacturing process. When used in conjunction, these solutions and processes can drastically improve the overall efficiency of the supply chain. It also contributes to the circular economy and sustainability initiatives that prioritize reuse and recycling over traditional disposal methods.

This circular model focuses on reducing waste and pollution, keeping products and materials in use, and regenerating natural systems. Approaches like these offer several key benefits to all parties involved, including:

- Improved Resource Utilization: The efficient management of inventory and logistics ensures that resources are used optimally, minimizing waste and overstock situations. Rather than relying on guesswork, users can access accurate data to generate forecasts and determine what to stock up on and what to scale back on.

- Reduced Waste: By integrating inventory management software with logistics supply chain management, businesses can limit waste generation in their operations. What’s more, efficient logistics management helps to reduce the environmental impact of transportation, such as fuel consumption and emissions.

- Sustainability Exchange: A sustainability exchange model refers to the sharing of knowledge and resources among stakeholders to improve sustainability. Integrating inventory management software with logistics supply chain management can facilitate sustainability exchange by providing businesses with the tools and data they need to collaborate effectively.

- Long-Term Competitiveness: Embracing sustainability in logistics and supply chain management benefits the environment, but many fail to realize that it also boosts the long-term competitiveness of businesses. By optimizing resource utilization, organizations can lower their operating costs and strengthen their brand image.

Ultimately, the importance of sustainability in supply chain management lies in its ability to centralize operations. This helps keep everyone aligned on common goals and objectives and allows organizations to work in a more climate-conscious manner, which is extremely important in today’s business landscape.