As a refresher, the International Organization for Standardization (ISO), is an independent, non-governmental international organization that develops and publishes standards to ensure the quality, safety, and efficiency of products, services, and systems. ISO standards are designed to be used globally, helping businesses and organizations achieve consistent performance and reliability. A well-known example of an ISO standard is ISO 9001, which focuses on quality management systems and is used across industries worldwide.

ISO 59004, ISO 59010, and ISO 59020 are the first globally recognized standards dedicated to Circular Economy (CE), setting the stage for businesses to understand and implement more sustainable and circular practices with a shared vocabulary, examples of business models to sustainably grow profits, and metrics to track progress.

The three initial standards were developed to address specific needs across industries.

- ISO 59004 was developed in response to the demand for a consistent terminology. This standard establishes a unified approach in the language we use to describe the circular economy.

- ISO 59010 provides business guidance for the transition to a circular economy and unpacks the difference between value networks and value chains.

- ISO 59020 is intended to act as a guide for tracking impact and providing robust methodologies to quantitatively evaluate circular economy practices.

Key contributions of the standards

As organizations face increasing pressure to adopt sustainable practices, the newly released ISO circularity standards provide a comprehensive framework for driving meaningful change. These standards not only clarify the path to circularity but also offer practical tools to help businesses measure and improve their performance.

The ISO 59004 standard defines the circular economy as “an economic system that uses a systematic approach to maintain a circular flow of resources by recovering, retaining, or adding to their value while contributing to sustainable development.” This definition lays the groundwork for how organizations can approach circularity with a consistent and clear framework.

A key contribution of ISO 59004 is its adaptation of the ‘waste hierarchy,’ [Reference: Reslan et al., 2022; Mathur et al., 2023] which defines various recovery processes and end-of-use recovery pathways. This guidance to resource management ensures that terminology across industries remains consistent, a crucial factor for implementing effective strategies to preserve the value of products, components, and materials. Clear terminology also helps organizations navigate recovery pathways, reducing valuable material waste and decreasing reliance on virgin resources.

| Action | Description |

|---|---|

| Refuse | Make solutions redundant by abandoning its function or by offering the same function with a radically different solution. |

| Rethink | Reconsider design and manufacturing decisions. Make service use more intensive (e.g., through sharing or by putting multi-functional products on the market). |

| Circular Sourcing | Select recovered or renewable, sustainably sourced or produced resources. Use resources that can be easily recycled or returned to the biosphere. Reconsider formulations. |

| Reduce | Increase efficiency in product manufacture or use by consuming fewer natural resources and materials. |

| Repair | Restore a defective or damaged product so that it can be used in its original function. |

| Re-use | Re-use a discarded product which is still in working condition and fulfills its original function. |

| Refurbish | Restore to a useful condition during expected service life with similar quality and performance characteristics. |

| Remanufacture | Return an item, through an industrial process, to a like-new condition from both a quality and performance perspective. |

| Repurpose | Adapt a product or its parts for use in a different function than it was originally intended without making major modifications to its physical or chemical structure. |

| Cascade | Shift recovered materials from one loop to another to optimize feedstock flows through additional cycles, often with decreasing quality and quantity. Cascading implies repeated use of renewable resources at decreasing quality. |

| Recycle | Recover and process material to obtain the same (high grade) or lower (low grade) quality through activities such as recovery, collection, transport, sorting, cleaning, and re-processing. |

| Recover Energy | Generate useful energy from recovered resources. |

| Re-mine | Mining or extraction from landfills and waste plants can be possible in some cases if mining or extraction activities are sustainably managed. |

| Table 1. Guidance for resource management actions from ISO 59004:2024 Circular Economy—vocabulary principles and guidance for implementation. | |

The ISO 59010 standard builds on this by guiding organizations of all sizes, sectors, and regions through the transition to a circular economy. It emphasizes a holistic approach, encouraging businesses to map their entire value chain and network to understand the broader context of their operations. This understanding is essential for setting boundaries and evaluating current circularity performance. By focusing on actions such as design for circularity, circular sourcing, and industrial symbiosis, organizations can improve their performance while contributing to a more resilient, sustainable economy.

ISO 59020 tackles the challenge of quantifying circularity. The standard provides a robust taxonomy for circularity indicators, which allows organizations to track material inflows and outflows, creating a clear picture of their circular performance. This structure not only helps companies evaluate their progress but also ensures comparability across industries and regions, allowing for meaningful benchmarks and improvements.

These standards collectively offer organizations a roadmap for embedding circularity into their operations. By integrating these frameworks, businesses can unlock new opportunities for innovation, efficiency, and sustainability, positioning themselves as leaders in a rapidly evolving global marketplace.

It is meaningful to understand the value embedded within these standards, but why were these standards created in the first place, and what impact will they have on your organization?

The journey to a new framework

The timing of these standards is no coincidence. With global sustainability goals looming, the ISO Circular Economy Technical Committee Working Group (ISO/TC 323) recognized the urgency of providing a standardized approach to the circular economy. A lack of consistent frameworks, guiding principles, and supporting tools was impeding the ability for businesses and organizations to contribute towards the UN’s Sustainable Development Goals (UN SDGs).

These published standards are foundational frameworks that aim to harmonize our collective understanding of a circular economy, its vision, and the principles behind its implementation. These standards serve to accelerate our transition to a circular economy, thereby contributing to the UN SDGs.

These standards address this gap by providing a framework that everyone—from industry leaders to newcomers—can understand and implement.

The publication of these standards was no small feat. The excitement around these standards was palpable, but it was also a lot of hard work—many early mornings and deep dives into the nuances of circularity. As a new member of the ISO working groups, it’s been a learning experience, and this is just the start. I’m eager to contribute to future standards.

The pros and cons

ISO 59004, in particular, stands out for its adaptation of the ‘waste’ hierarchy—a concept familiar to many, but now applied with a new lens. From a manufacturing perspective, this hierarchy is essential for preserving the value of products, components, and materials. Consistency in recovery terminology is one of the first steps in keeping valuable materials out of landfills and reducing our reliance on virgin resources.

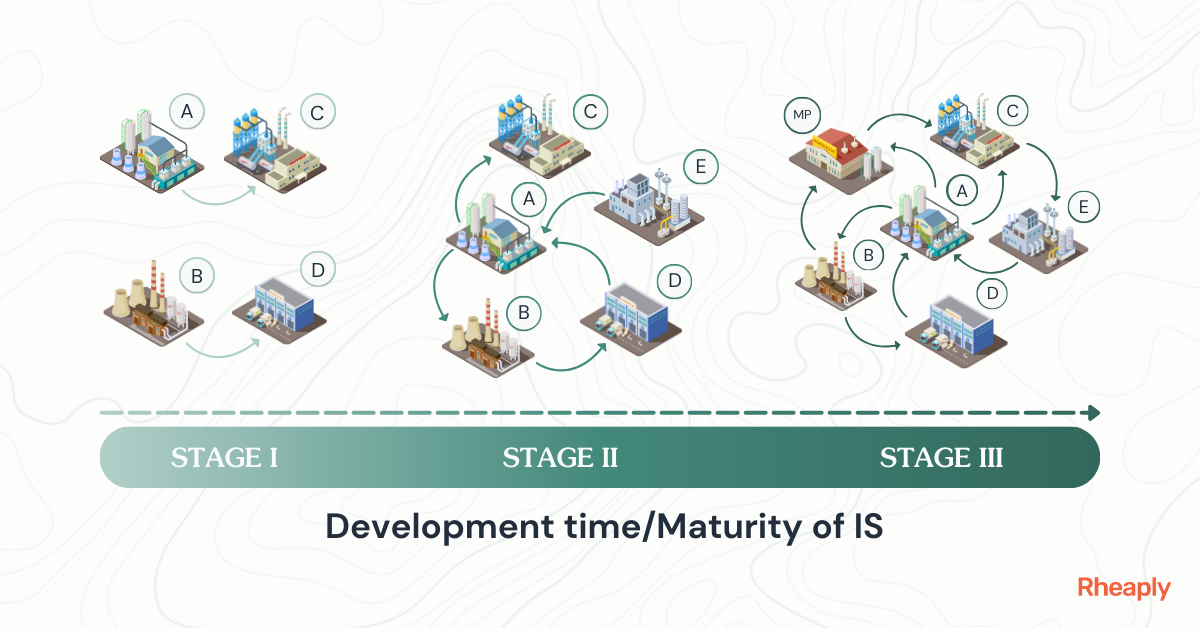

However, there’s still room for improvement, particularly around the concept of Industrial Symbiosis. The National Institute for Standards and Technology (NIST) and Rheaply collaborated to create benchmarks for developing and continuously assessing symbiotic networks. These benchmarks outline the progression from ad-hoc byproduct exchanges to more coordinated inter-firm efforts, eventually leading to a system with high levels of resource circulation and utilization.

Our findings are published in the report Investigating the use of network analysis metrics to benchmark Industrial Symbiosis development. We hope that in the coming months and years, results from this work becomes embedded in global CE standards.

Figure 1. An illustration presenting the various developmental stages of Industrial Symbiosis form the report “Investigating the use of network analysis metrics to benchmark Industrial Symbiosis development.” Firms A to E correspond to the participating companies, MP refers to a municipal partner, and the arrows depict the flow of resources between them.

Takeaways

Reflecting on the development and implications of these standards, three key takeaways emerge:

- The published standards are foundational, as they effectively bridge a significant gap in terminology. This harmonization enhances our understanding of the circular economy (CE) across various regions and industry sectors.

- There is still a need to develop robust technical methodologies for measuring and quantifying the implications of implementing CE practices. Given NIST’s expertise in advancing measurement science, we anticipate greater involvement in ISO TC 323 in the coming months and years.

- Transitioning to a circular economy involves many stakeholders and is inherently interdisciplinary. TC 323 recognizes that different industry sectors and regions may require distinct support mechanisms for this transition. To ensure that CE is equitable and inclusive, it is important to acknowledge these differences.

The release of the ISO circularity standards is more than just a milestone—it’s a call to action for businesses worldwide. By adopting these standards, organizations can take meaningful steps towards sustainability, paving the way for a more circular and resource-efficient future.